Sluggish line speed is generally appropriate for assessing manufacturing processes involving prolonged aseptic exposure in the sterile drug item and containers or closures.

Analytical cookies are accustomed to know how guests interact with the website. These cookies assistance offer info on metrics the number of visitors, bounce rate, targeted visitors resource, and so on. Advertisement Ad

; and so on.) need to be monitored no less than as soon as daily and the final results documented on the temperature log. Additionally, pharmacy personnel should Take note the storage temperature when placing the product into or eliminating the products through the storage device as a way to observe any temperature aberrations. Ideal temperature recording equipment could include things like a calibrated steady recording product or an NBS calibrated thermometer that has satisfactory precision and sensitivity to the intended intent and may be adequately calibrated at suited intervals.

one. Just one contaminated device really should cause an investigation, which include thing to consider of repeat media fill;

Calibration packages shall be in place for incubators, environmental monitoring test gear, and laboratory instrumentation used for Media Fill Test scientific tests and all calibrations needs to be current ahead of applying any machines and instrument.

These threat degrees use to the caliber of CSPs immediately once the last aseptic mixing or filling or immediately following the remaining sterilization, Unless of course precluded by the particular properties in the planning, which include lipid-primarily based emulsions wherever administration must be finished in twelve hrs of planning. On subsequent storage and delivery of freshly concluded CSPs, a rise in the challenges of chemical degradation of ingredients, contamination from physical harm to packaging, and permeability of plastic and elastomeric packaging is predicted.

Length on the media fill trial was much more than that essential to the regimen manufacturing Procedure.

The identification with the contaminating organism shall be in comparison to the databases of your organisms identified inside the ability in the environmental checking program.

Definition of Media Fill and Necessities with the Pointers: – In keeping with all guidelines the procedure simulation with media fill is point out of your artwork to the validation of aseptic manufacturing approach. Media fill implies that a microbiological nutrient media is going to be filled into a container closure method (ampule, vials etc) instead of the item under simulation of aseptic conventional technique.

Our exceptional shade indicator adjustments from pink to yellow within the existence of contamination. Mitigate the hazards of Fake good and Phony adverse final results for MFT with simple-to-browse TSB media.

The objective of website the validation is to establish documented proof that the process for aseptic processing of parenterals liquid/ophthalmic Answer will pass the acceptance conditions continually, when executed as per the Typical Functioning Methods.

Chemotoxic and also other hazardous CSPs require safeguards to take care of the integrity with the CSP and to reduce the exposure opportunity of those goods into the natural environment and also to staff who may possibly are available in connection with them. Specific specifications associated with the packaging, transport, and managing of those brokers consist of the avoidance of accidental exposures or spills as well as read more the training of personnel during the function of the exposure or spill. Examples of Exclusive needs of such brokers also include things like exposure-reducing methods such as the utilization of Luer lock syringes and connections, syringe caps, the capping of container ports, sealed plastic baggage, impact-resistant containers, and cautionary labeling.

In the course of Media Fill, the incubation temperature should be suited to the recovery of bioburden and environmental isolates and will by no means exceed twenty-35oC. The temperature of the incubation chamber really should be stored in just ±2.5oC on the target temperature. The incubation time period really should not be shorter than 14 days.

Immediately perform the sterilization of LVP holding tank along with ultimate filter and item line of bottle packaging machine According to its respective SOP.

Yasmine Bleeth Then & Now!

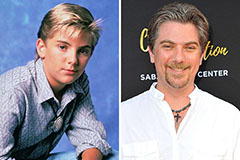

Yasmine Bleeth Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Danny Pintauro Then & Now!

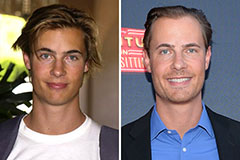

Danny Pintauro Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now!